FlexiCAM GmbH

Booth number: Ar D240

www.flexicam.com

About us

FlexiCAM is one of the industry leaders in CNC machining technology, specializing in custom-designed 3-, 4-, and 5-axis CNC machining centers. With a robust portfolio of products tailored to meet the demands of complex sectors such as aerospace, automotive, construction/facades, architecture, and more, FlexiCAM has established itself as a go-to partner for companies requiring precise, efficient, and scalable machining solutions. Our machines can handle a broad spectrum of materials, from aluminum and advanced composites to plastics, acrylics, foams, and specialized materials used in model and pattern making.

We offer both standard machine models and highly customized solutions, ensuring each machine meets the unique needs of our customers. FlexiCAM’s services extend globally, providing pre- and post-sales support to ensure our clients achieve optimum results.

Address

Benkertsweg 9

D-97246 Eibelstadt

Germany

E-mail: info@flexicam.com

Phone: +49 9303 90810

Internet: www.flexicam.com

P.O. Box 41752

Sharjah

United Arab Emirates

E-mail: info@flexicam.com

Phone: +971 6 5263307

Internet: www.flexicam.com

Contact person:

Ashfaq Qadri

Business Manager

E-mail: aqadri@flexicam.com

Phone: +971 50 3686758

Products & Services

Through continuous innovation and an unwavering commitment to delivering top-quality products at an exceptional price-performance ratio, FlexiCAM has established itself as a global leader in the field of 3-, 4-, and 5-axis CNC machining centers.

FlexiCAM offers state-of-the-art manufacturing solutions for a wide range of industries including aerospace, boat building, automotive, railways, buildings, and provides machining for materials such as aluminum, composites, plastic, ACM, ACP, acrylics, foam and more.

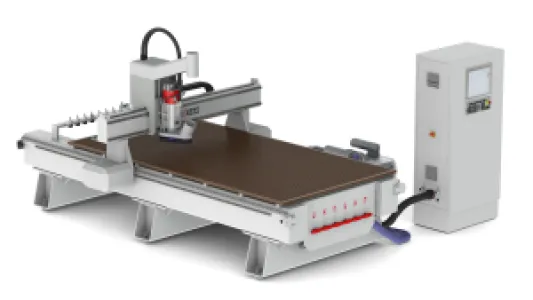

FlexiCAM Stealth CNC Machining Center

The FlexiCAM Stealth delivers exceptional performance with its robust engineering and durable construction. Built on a single-piece, rigid steel base frame with a 12mm thick tubular structure, its design is stress-relieved and FEA-analyzed for superior strength and precision. Ideal for medium to heavy production, the Stealth efficiently handles materials such as wood, acrylic, PVC, aluminum, and composite materials like ACM and fiberglass. Its customizable work table offers configurations up to 6 meters in length, with Z-axis clearance options of 200 mm or 300 mm. Compatible with FlexiCAM’s Advanced Control System (ACS) or industry-standard Siemens and Fanuc controls, the Stealth ensures reliability and versatility for demanding applications.

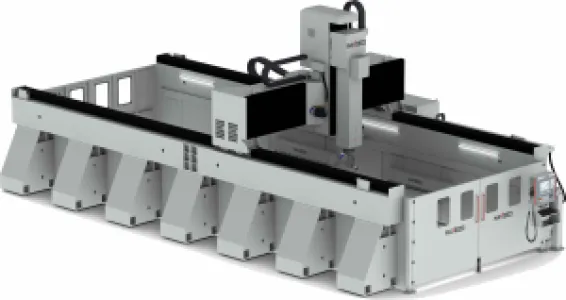

FlexiCAM XL CNC Machining Center

The FlexiCAM XL has been specifically engineered to cater to the needs of high-production shops, and is equipped with our powerful AC Servo drive system as a standard feature. These machines are highly suitable for demanding applications such as machining non-ferrous metal, solid surfaces, and plastic parts. They have been designed to operate in production-type environments and are capable of handling a broad range of manual tool change and automatic tool change spindles to meet specific application requirements, such as architectural fixtures, dimensional signages, and molds.

The XL's foundation is constructed using heavy welded tube on tube design, creating a single, sturdy unit. The machine is customizable with various options available from FlexiCAM, including but not limited to, Rotary Axis, C-Axis, Siemens and Fanuc Controls, I-Cut Vision, Auto Lubrication, and more.

FlexiCAM Ultimate CNC Machining Center

FlexiCAM Piranha CNC Machining Center

The FlexiCAM's Piranha 5-Axis CNC machining center is specifically designed for high-speed machining of large-sized workpieces such as manufacturing patterns, moulds, jigs, prototypes, and trimming of large-scale composite parts in the aerospace industry. The machine is capable of handling sizable workpieces, with a work envelope that measures up to 60 meters in length, 7 meters in width, and 5 meters in height.

The Piranha features powerful spindles capable of generating up to 25 KW of power and can operate using either the FlexiCAM Advanced Control System (ACS) or an industry-standard Siemens or Fanuc control system. It is particularly effective in processing large parts that require extended axis travels, a long stroke, and considerable height under the gantry.

To enhance the machine's efficiency, FlexiCAM provides a range of additional options, such as multiple gantries, optical (laser) or mechanical probes, palette changers for workpieces, dust collection systems, and other features.